About Our

Services

When it comes to meeting your manufacturing needs with precision and excellence, VyComp Production Machining has reliable track record of meeting any needs you may have. As a trusted family-owned machine shop, we take immense pride in delivering consistent quality, with great attention to detail reliably. Whether you require manual milling, manual lathe work, , CNC milling, CNC lathe services, welding, or assembly services, we are your go-to solution.

We help customers in a wide range of industries meet their manufacturing needs and secure their supply chain. Whether producing machined metal components, plastic parts, or more complex assembly and welding products we are a reliable partner.. When outside processes are required, such as heat treating,plating, or speciality manufacturing services, we draw on over twenty years of experience and partnerships with high quality domestic and international vendors. We deliver excellence, no matter what it takes, to guarantee our customers expectations and timelines are met. That’s why customers all across the country keep coming back to Vycomp to solve their manufacturing challenges.

1

MANUAL MACHINING

Our skilled machinists, many with over 20 years of experience, have the knowledge and precision necessary to execute custom work with meticulous attention to detail and exceptional accuracy.

Our team operates with a range of high-quality machines, including two Bridgeport milling machines, a Supermax, and a PM 932 Precision Matthews. These machines are renowned for their reliability, versatility, and ability to handle a wide variety of projects. Equipped with advanced features and precise controls, they allow our machinists to achieve remarkable results.

From simple designs to intricate geometries, we are committed to ensuring that every aspect of your project meets your exact specifications. Our machinists take the time to fully understand your requirements, working closely with you to translate your vision into reality. They meticulously plan and execute each step of the machining process, ensuring that every cut, shape, and finish is executed with utmost precision.

Throughout the manufacturing process, our team adheres to stringent quality control measures. Regular inspections and meticulous checks are performed to verify that each component meets the highest standards of accuracy and craftsmanship. We understand the importance of delivering not just a functional product, but one that embodies excellence in both form and function.

Whether you require a one-off custom piece or a production run of intricate parts, our skilled machinists are dedicated to delivering results that exceed your expectations. Their expertise, coupled with our state-of-the-art machinery, ensures that we can tackle a wide range of projects with confidence and efficiency.

We take great pride in our ability to provide personalized, custom work that is tailored to your specific needs. By combining the expertise of our machinists with our advanced equipment, we are able to deliver outstanding craftsmanship, remarkable accuracy, and exceptional attention to detail. Partner with us and experience the difference that our skilled team can make in bringing your visions to life.

2

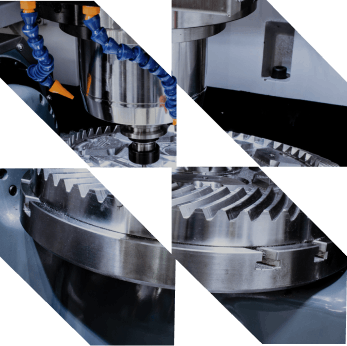

CNC Milling

Our CNC milling services are reliable and efficient, and a great solution when every detail matters. We have a wide selection of CNC Mills suited for a variety of machining tasks allowing us to handle many complex operations and projects:

- Haas VF-2: The Haas VF-2 is renowned for its precision and versatility. With its advanced 3-axis capability, it provides exceptional cutting and shaping capabilities for a wide range of materials. This machine is a reliable workhorse for achieving intricate part designs.

- Two Haas VF-3 3-axis with 4th axis capability: Our two Haas VF-3 milling machines combine precision and flexibility. With their 3-axis capability and the added versatility of a 4th axis, they can handle complex geometries and demanding machining tasks with ease.

- Haas VF-3YT 3-axis with 4th axis capability: The Haas VF-3YT takes CNC milling to the next level. With its extended Y-axis travel and 4th axis capability, it offers enhanced capabilities for tackling larger parts and more intricate designs.

These cutting-edge CNC milling machines empower us to deliver meticulous cutting and shaping for the seamless creation of intricate parts. Whether you require rapid prototyping or high-volume production, our services are designed to meet your specific needs. We guarantee consistent and dependable outcomes, ensuring that every part meets the highest standards of precision and quality.

Our team of skilled technicians and operators leverages the capabilities of these machines to optimize efficiency and achieve exceptional results. We are committed to providing you with the highest level of accuracy, reliability, and productivity throughout the entire manufacturing process.

3

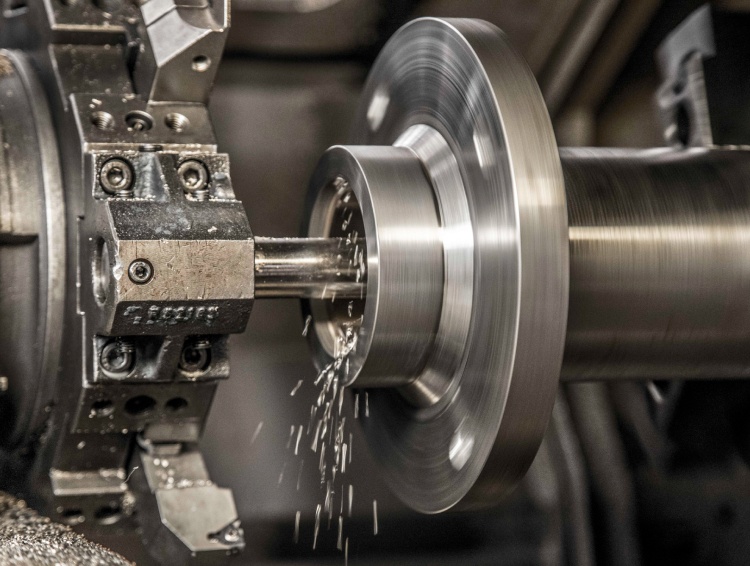

CNC LATHE

Our commitment to precision and productivity is exemplified in our history of completing complex and challenging turing operations for mission critical operations. These cutting-edge machines enable us to handle a wide range of materials and tackle complex geometries with utmost accuracy and efficiency.

Our exceptional lineup of CNC lathes:

- Haas HL-2 with 4ft Bar Feed: This lathe is equipped with a 4-foot bar feed, enhancing its capabilities for automated and continuous machining processes. It offers excellent control and precision, making it suitable for a variety of applications.

- Haas ST-30: With its advanced features and robust construction, the Haas ST-30 delivers exceptional performance. It boasts remarkable rigidity, high spindle speeds, and superb tooling capabilities, ensuring precise machining of complex parts.

- Doosan Puma GT2600M with 4ft Bar Feed: The Doosan Puma GT2600M offers impressive power and versatility. Its 4-foot bar feed allows for efficient operations, while its advanced control system and turret configuration enable multi-tasking and enhanced productivity.

- Doosan Puma GT2100 with 4ft Bar Feed: This lathe combines speed, accuracy, and flexibility. The Doosan Puma GT2100, with its 4-foot bar feed, can handle a wide range of machining tasks while maintaining precision and stability.

- Two Suga ST-100 with 12ft Bar Feed: The Suga ST-100 is a workhorse when it comes to large-scale machining. These lathes provide exceptional stability and precision for demanding projects.

With this diverse array of CNC lathes, we have the capability to tackle projects of varying complexity, size, and material requirements. Our CNC lathes empower us to deliver exceptional results, ensuring your parts are manufactured with the highest levels of accuracy and productivity.

4

Assembly

Count on our assembly services for seamless integration and attention to detail. Our team will ensure proper fit, functionality, and adherence to your specifications. We deliver fully assembled products that are ready for use or further processing.

Contact us today

Contact us today to learn more about how we can help you with your machining project.